Uni-Mill Engineering Ltd began as a ‘jobbing shop’ where offering a complete one stop shop was necessary to fully service all customer requirements. As the company evolved into a sub-contract machining facility, it strived to maintain these additional skills making Uni-Mill an attractive prospect for any potential customers looking for a complete service provider. The many additional processes available at Uni-Mill are not exhaustive as we have spent years fostering professional working relationships with fabrication, casting, forging, PTFE coating, painting and many more suppliers to ensure that we are still able to offer a one stop shop service at a competitive price.

We have a conventional toolroom mainly used for in house tooling production and apprentice training.

We have 2 grinding machines used for making precision in house tooling and fixtures.

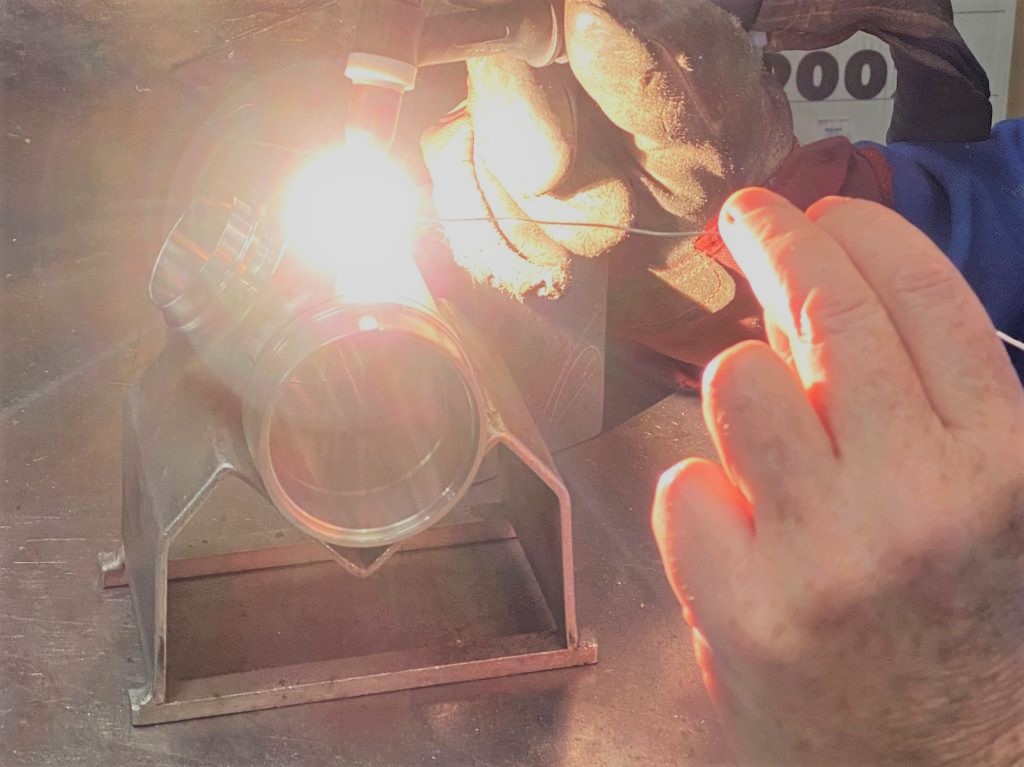

We specialise in CNC and hand welding of stainless, aluminium and aluminium bronze sub assemblies or fabrications.

Fully equipped fettling department to support production, prep for second op production and post weld dressing.

3 spark eroding machines generally used for second op processes that cannot be easily/efficiently machined.

We offer beadblasting on stainless steel, aluminium and aluminium bronze with a range of blast media.

On hard to reach areas, we offer burr inspection and post production deburring to customer specifications

We use a MEG solvent cleaner for parts made in oil, and detergent for parts made in white water coolant.

We use an automated printing head to ink mark on circular and box components to aerospace standard.

We offer a range of assembly services from inserting Helicoils to complete manufactured assemblies.

Our machine allows us to offer an over-braiding and magneform service carried out to customer specification.

We then securely pack, despatch with full paperwork and ship to your door using a range of courier options.

Due to the size of our site, Uni-Mill Engineering Ltd are in the position to offer a number of stocking options for customers to guarantee future business. This stock is normally covered by a contract or purchase order allowing us to manufacture in higher volume and deliver over an extended time period.

The main benefits are:

With this scenario, we all win. The customer receives a competitive price and the best possible service while Uni-Mill are able to guarantee a returning customer.